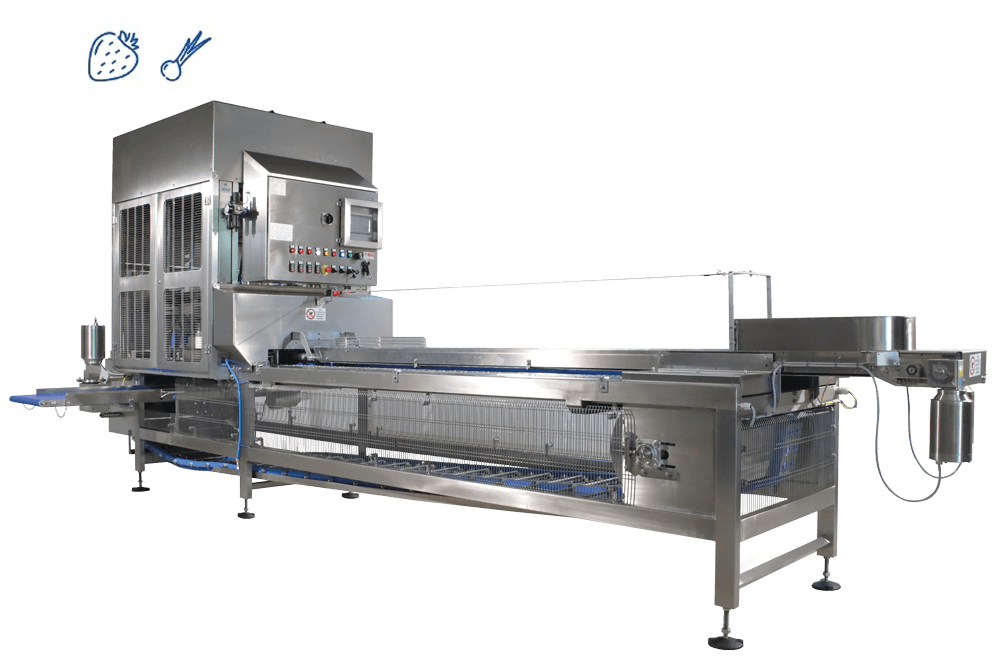

DE-CALYX MACHINE

The DF12/DF24 destalking machine is designed for the destalking and cutting of strawberries and radishes into halves or quarters. It is an instrument designed to reduce manual labour without sacrificing delicate processing and while avoiding mechanical damage to the fruit. The standard model includes a merry-go-round infeed conveyor belt that allows operators to always have product available for loading. The product is placed manually in the special fruit holders that rotate continuously, taking the product to the process stations. The processing takes place in three phases: the alignment of the product; the destalking and the ejection of the fruit (which may coincide with the cutting phase, if requested by the customer). The device allows the dry product to be processed, without the need for water, with minimal waste (around 10%).

The DF12/DF24 destalking machine is designed for the destalking and cutting of strawberries and radishes into halves or quarters. It is an instrument designed to reduce manual labour without sacrificing delicate processing and while avoiding mechanical damage to the fruit. The standard model includes a merry-go-round infeed conveyor belt that allows operators to always have product available for loading. The product is placed manually in the special fruit holders that rotate continuously, taking the product to the process stations. The processing takes place in three phases: the alignment of the product; the destalking and the ejection of the fruit (which may coincide with the cutting phase, if requested by the customer). The device allows the dry product to be processed, without the need for water, with minimal waste (around 10%).

It is equipped with:

• merry-go-round infeed conveyor belt. Dimensions: 3700×300 mm.

• processed fruit conveyor belt for product outfeed.

Dimensions: 1800×300 mm.

Technical features

| Technical features | DF24 | DF12 |

|---|---|---|

| Production capacity | 450 fruits/min | 225 fruits/min |

| Machine dimensions (width x length x height) | 6200x1360x2100 mm | 5500x1185x2500 mm |

| Weight | 1800 kg | 1800 kg |

| Installed power | 3 kW | 1.5 kW |

| Water supply pressure (min) | 3 bar | 3 bar |

| Water consumption | 1.6 l/min | 1.6 l/min |

| Pneumatic supply (min) | 5 bar | 5 bar |

| Air consumption | 50 NL/min | 70 NL/min |

| Cut (min/max) | 2-4 | 2-4 |

| Employee operator | 8 | 4-6 |

Company Information